Nowadays, more and more industries have recognized the benefits of building pre-engineered steel buildings over conventional buildings. There has been a steady increase in commercial properties, warehouses, offices, hangars, retail spaces, and other structures that have utilized this construction method. For good reason, using the components of pre-engineered steel buildings provide projects with cost-effectiveness, added durability, time efficiency, sustainability, and customizable design options.

Pre-engineered metal buildings use prefabricated components that are delivered in a completely knockdown condition (CKD) and assembled on the site using cranes. There are numerous parts of pre-engineered steel buildings that provide shape and support to the structure. Continue reading to learn more about these.

For every building, there should be a stable framing that supports the horizontal and vertical loads of the entire structure. It should be strong enough to never compromise the project’s structural integrity.

For pre-engineered steel buildings, the primary frame is made up of rigid steel columns and rafters that are attached together using fittings such as flanges. The tapered components are used to support the poured concrete and the associated loads.

Fabricators should make sure the building’s primary frame can withstand environmental forces such as corrosion and natural calamities, which is why immense expertise is applied to its assembly. Keep in mind that the number of primary frames will also depend on the type and size of the pre-engineered steel building being constructed.

As mentioned before, a pre-engineered steel building’s framing is important as it supports the overall load of the structure. This being said, a secondary structural frame is an essential component as it transfers the loads to the primary framing effectively.

The secondary structural frame is mainly made of purlins, eave struts, and girts of Z or C shapes in various sizes. Pre-engineered steel buildings use these “Z” sections that are cold-formed with stiffened flanges for a high strength-to-weight ratio. Compared to other materials like wood, the advantage of pre-engineered buildings is a structure that needs less steel to bear the specific load resulting in a lighter frame.

The purlin components can be used on the roof, girts are used on the walls, and eave struts are used at the intersection of the sidewall and the roof. Typically, these are not welded. Instead, they are pre-fabricated by bending to give it their shape.

Cable bracing is another secondary structural frame member that ensures the stability of pre-engineered steel buildings against longitudinal forces such as winds and earthquakes. Diagonal cable bracing is used for the roof and sidewalls to reduce impacts.

Walls and roof panels are composed of various parts such as studs, ridge caps, bottom plates, headers, and top plates to provide weather coverage to the structure. They also protect the building from leaks, air infiltration, and wind uplift. This is where sheeting or cladding comes into the picture as well.

For all purposes, these covering panels provide access for design and function requirements. The steel sheets are normally galvanized and color coated to make the pre-engineered building achieve an aesthetic look. These structures are properly insulated through insulation rolls and the roofing steel sheet is fixed over it.

Once everything is complete for the assembly procedure, it is time to actualize. As stated above, cranes are used to build pre-engineered steel buildings. With this system, there is an improvement in handling parts and better utilization of space on the site.

It can also save you a significant amount of money in terms of labor costs.

There are various types of crane being used in pre-engineered buildings such as EOT overhead crane with pendant or cabin operated, overhung or under-slung crane system, monorail crane or hoist system, wall-mounted crane, or jib cranes. The choice will depend on the operational need.

Pre-engineered steel buildings are low-density structures that have a maximum of two intermediate floors and a roof. Mezzanines are another component found inside pre-engineered steel buildings made with steel decks supported by joists framed onto main beams. Keep in mind that loads of the mezzanine system are affected by column spacing. Mezzanine systems are a great option for projects that want to maximize space for production areas.

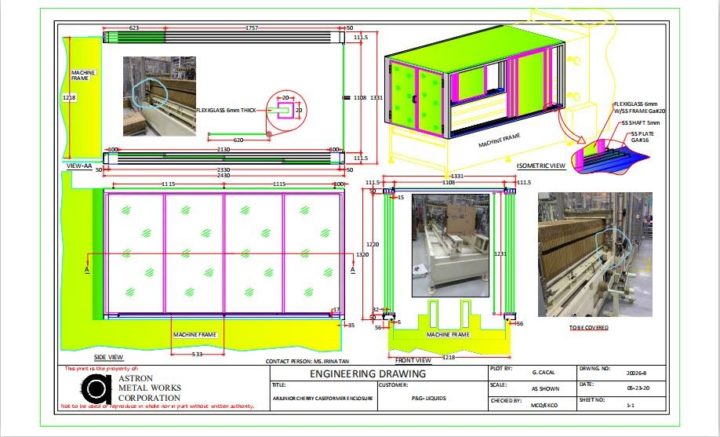

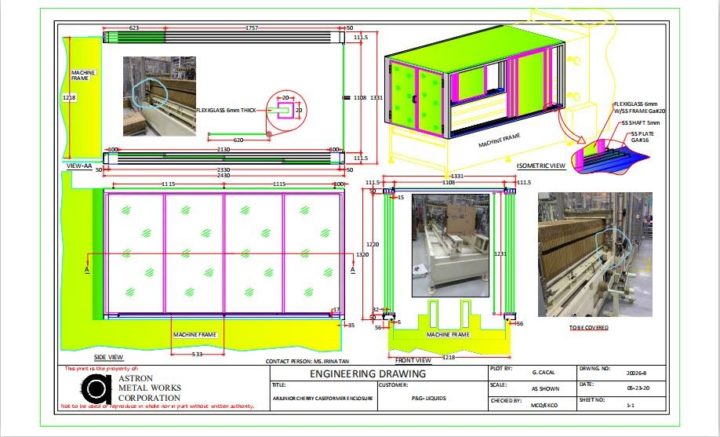

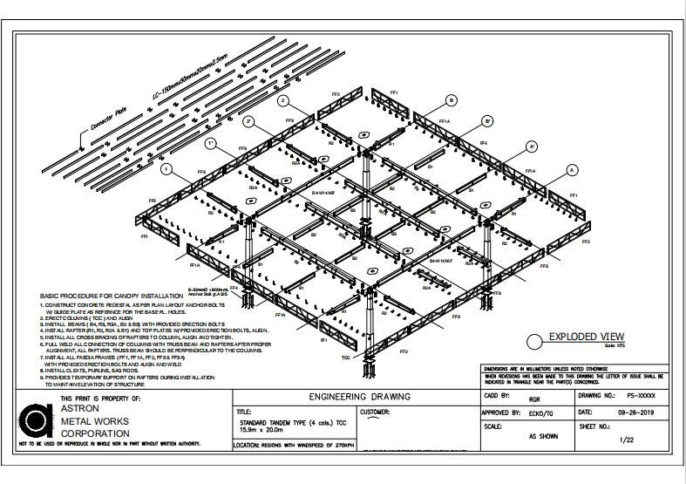

Components of pre-engineered steel buildings may not be vital structurally, however, they are very important to the functionality and aesthetics of the structure. It finishes up the overall look. These accessories include crane runway beams, catwalks, fascia, parapets, canopies, and roof extensions.

There’s no doubt about how beneficial pre-engineered steel buildings are for diverse industries. This type of structure boasts numerous advantages such as cost-effectiveness, durability, time efficiency, sustainability, and customizable design options, which are factors that cannot be found in conventional buildings.

With decades of experience in the steel industry, Astron Metal Works is the leading industrial fabricator in the Philippines. We can fabricate pre-engineered steel building components for your project. If you want to inquire about our services, click here.

What are the benefits of quality control in metal fabrication? Enhances safety Cost savings Compliance with industry standards Boosts customer loyalty When sourcing for an industrial fabricator in the Philippines, it’s crucial to choose one that has an in-house quality control procedure. In the metal fabrication and manufacturing industry alike, quality control is defined as […]

What are the techniques used in sheet metal fabrication? Shearing Cutting Bending Punching Assembling Sheet metal fabrication is defined as the manufacturing process of shaping sheet metal according to functional needs. Sheet metal is one of the most ideal materials for a wide array of industries because it is lightweight and immensely ductile. The techniques […]

What are the uses of CNC cutting services in the Philippines? Construction materials Food production items Metal furniture Gas station fixtures CNC cutting refers to the metal fabrication procedure that involves using computer numerical control routers with the advantage of versatility and flexibility being derived from automation. The computerized routers are adept in cutting […]

What are the uses of sheet metal fabrication? Construction Petroleum Industrial Industries Sheet metal refers to metal formed into thin sheets, typically by hammering or rolling. It is highly durable and able to maintain its structural integrity, making it easy to work as it can be bent, stamped, cut, dished, and punched. Sheet metal fabrication […]